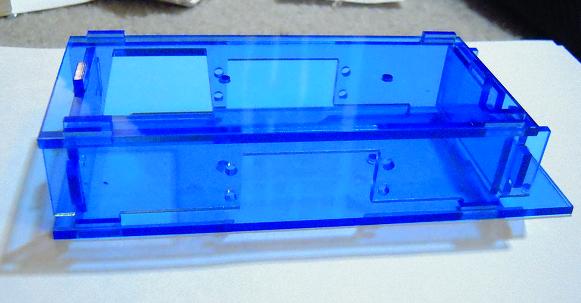

Finally, the Grisbot’s acrylic casing is being laser-cut, possibly even as we speak.

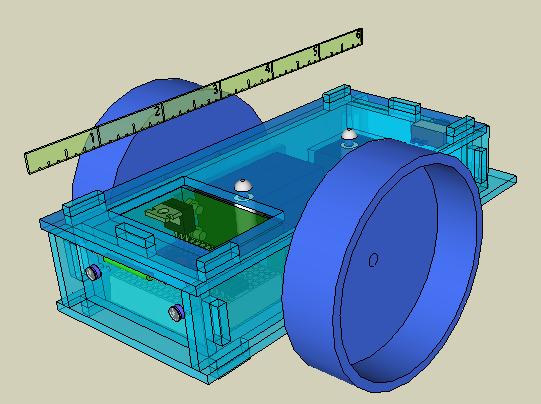

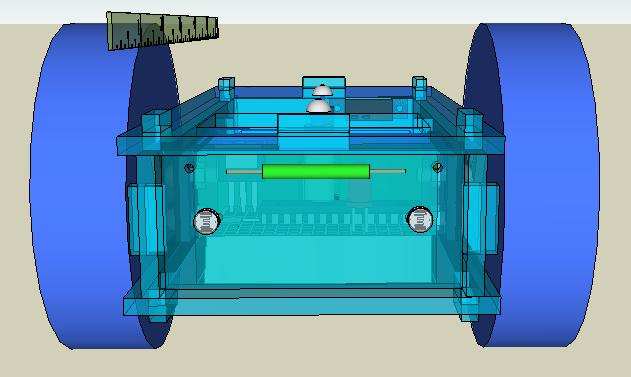

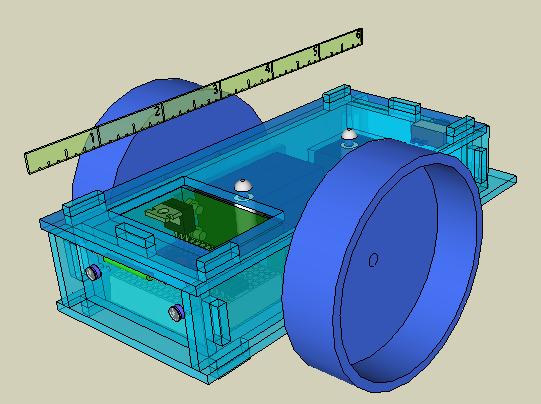

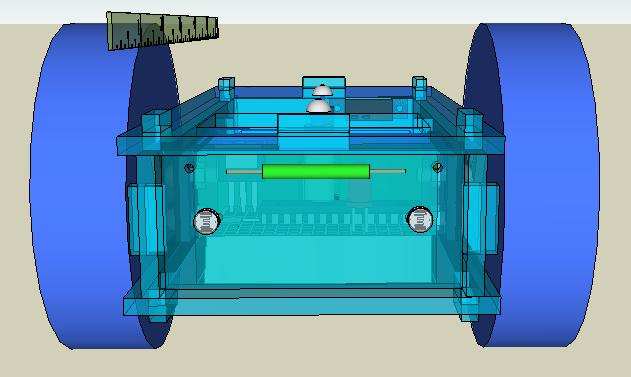

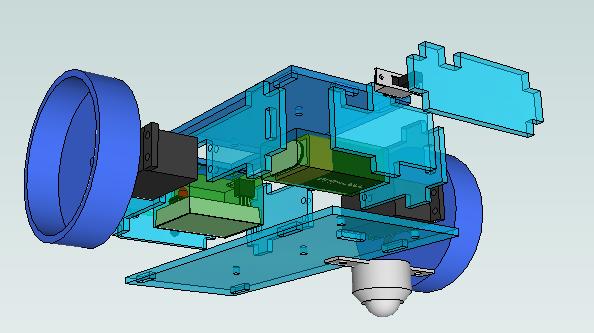

Here is a guided tour in Sketchup of what may actually come to be by the end of this week, starting with the front view:

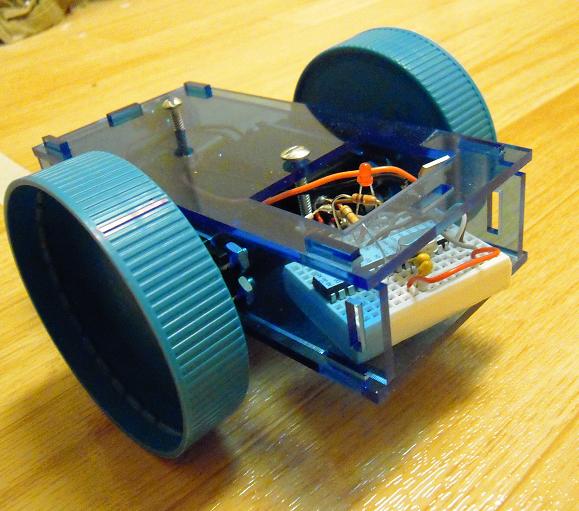

The ruler is for reference — ie, the vehicle is about six inches long. The two standoffs on the centerline secure the pieces together.

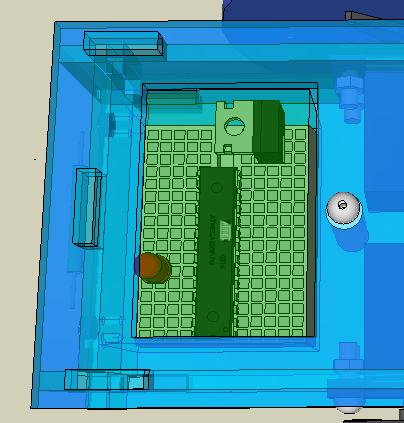

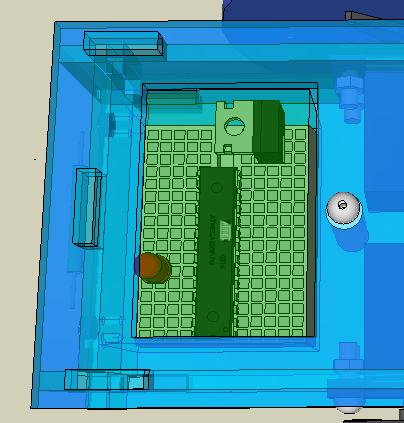

The upper view:

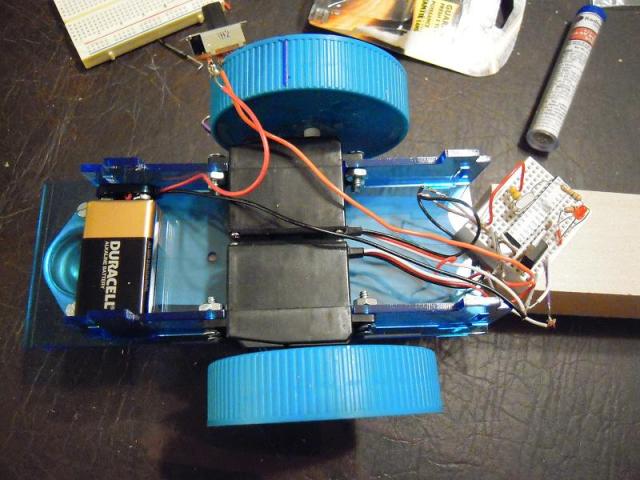

Moving from left to right, we see the layout of the breadboard with microcontroller, the servos and wheels, and the battery as ballast in back with the ball caster in tail-dragger configuration.

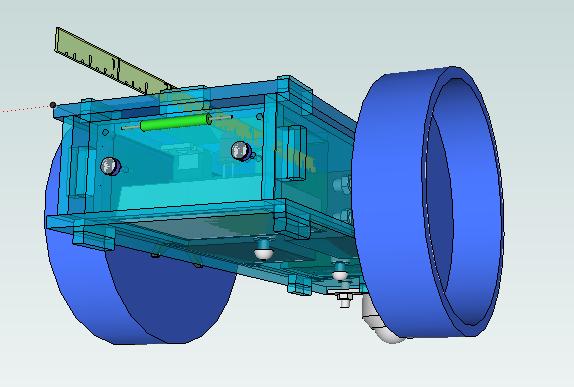

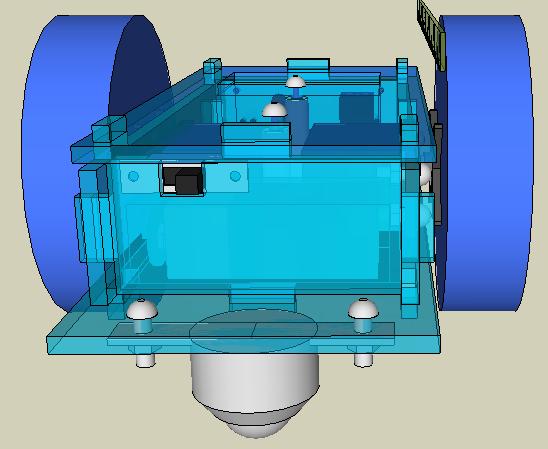

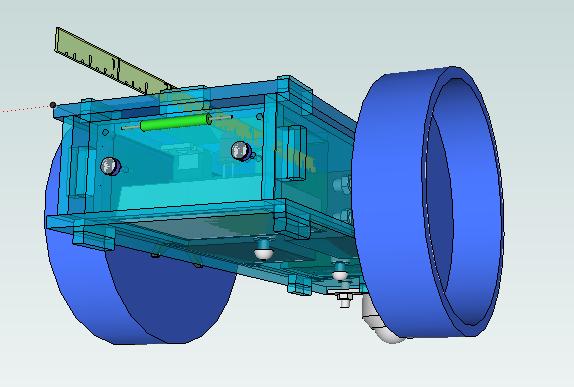

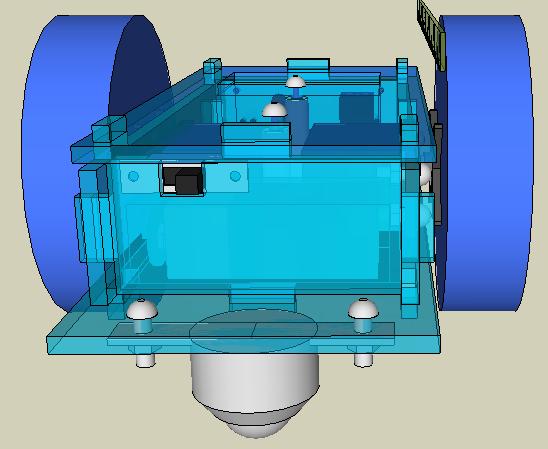

Here’s a lower view, showing how the robot rests on its two wheels and ball caster:

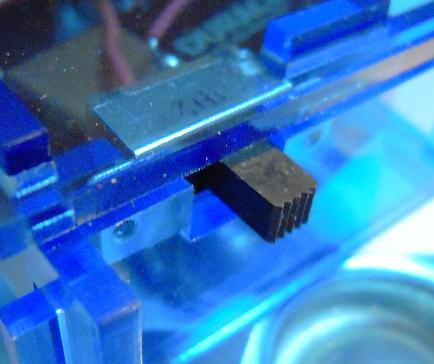

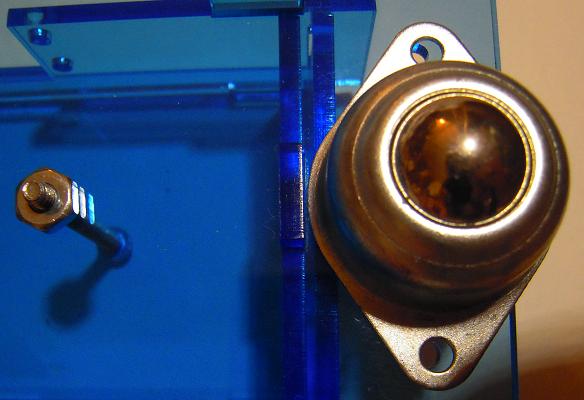

Here’s a closer look at the front grill:

There are two photosensors, one for data and one for the clock pulse. The magnetic reed switch at the top may be moved to the rear or replaced entirely by a manual toggle switch in the future.

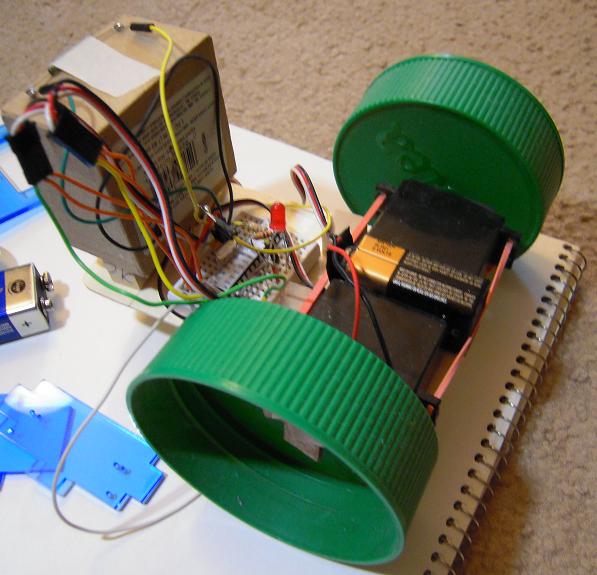

The side view of the wheel:

Plastic jar lids are just the right size and are inexpensive, lightweight and durable, have a wide tread for good traction and an injection-mold dimple conveniently placed to locate the drill hole for the servo axle screw.

A rear view:

The ball caster is bolted to a protruding lower ledge, which is large enough to accomodate a future trailer hitch. Also there is now an on/off switch.

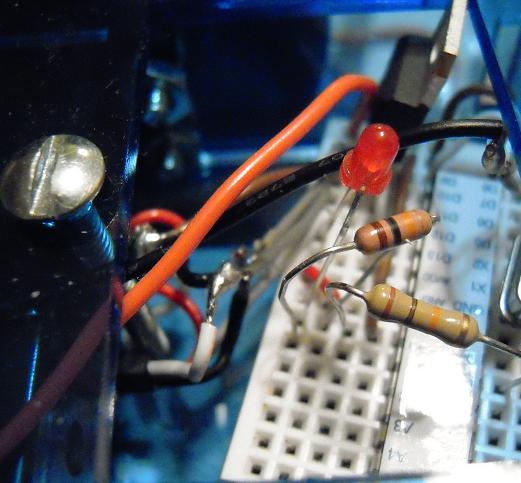

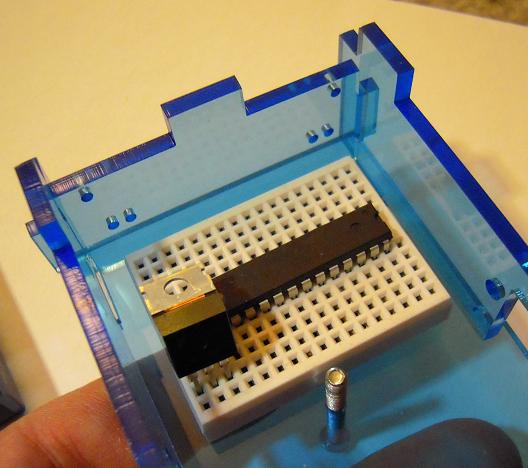

A close-up of the breadboard:

The ATMEGA328P microcontroller, fresh from being programmed atop an Arduino prototyping platform, is placed on the mini bread board. The 7805 voltage regulator has its heat sink bent horizontal to avoid jabbing fingers. The large access hole will be shrunk and/or covered with a hood (I’m thinking of how to do that).

(Note that wires have been omitted for clarity. Also the bread board components have been illustrated as being inside a greenish semi-transparent form box to better determine model fit.)

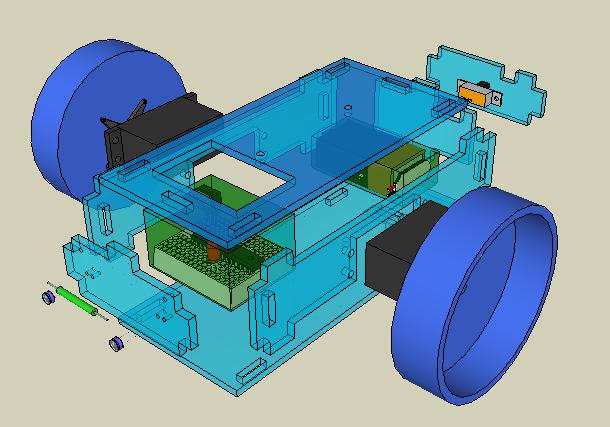

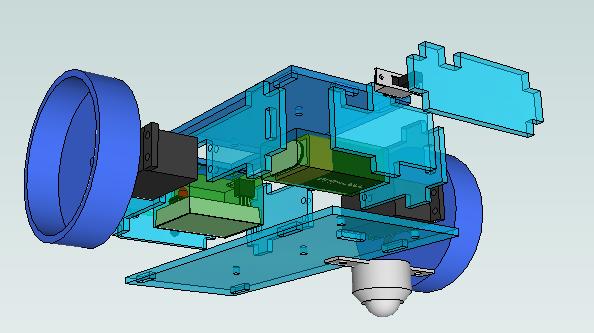

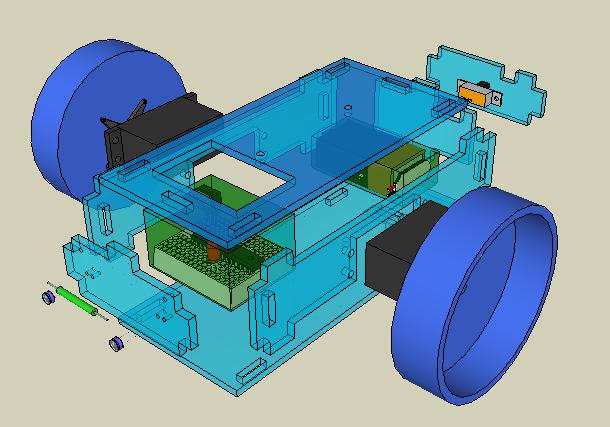

An expanded view:

This makes me think of a three dimensional puzzle, which indeed this exercise has been. Note that for clarity, I removed the standoffs and bolts from this illustration. (And again, the breadboard and battery too have been enclosed in imaginary form boxes for modeling purposes.)

An expanded view from the rear:

Note that the switch is secured by being sandwiched between two pieces of acrylic. I did that because the switch package from Radio Shack has the securing bolts but not the nuts. Maybe I could special-order them, but a couple extra square inches of acrylic don’t cost much and it was more fun to do it this way.

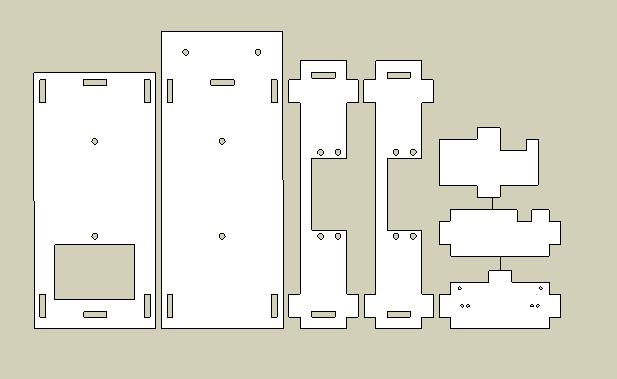

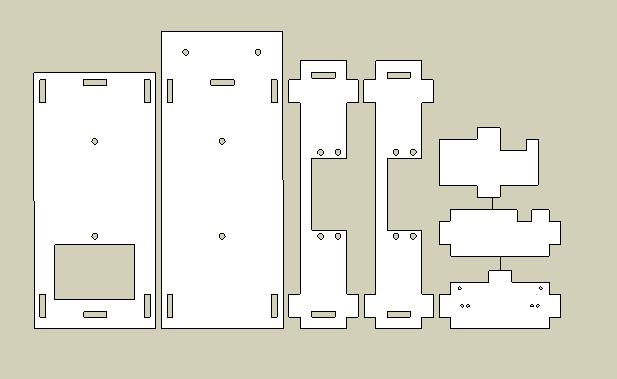

And finally, here are the surfaces prepared for export to SVG file:

Considering all the little details and potential for errors, I would be surprised if it all comes together tomorrow. But we’re getting closer.