In my continuing efforts to find a simple product to market, I thought, “Why don’t I make some upgrade mods to the conventional brushbot?” So I ordered a brushbot kit from Maker Shed, and modified as shown. The long green component is a reed switch, which is activated by proximity to a magnet. There is also a photo cell in parallel, so that the brushbot can also be activated by a light source.

How well does it work? Not very, either way.

If the magnet is ceramic, the reed switch won’t activate unless the magnet is touching. If the magnet is rare earth, it snaps to the reed switch so fast that it ends up touching whether you wanted it to or not. The hope of being able to activate the robot at a distance with the wave of a magic (= magnetic) wand is apparently not to be.

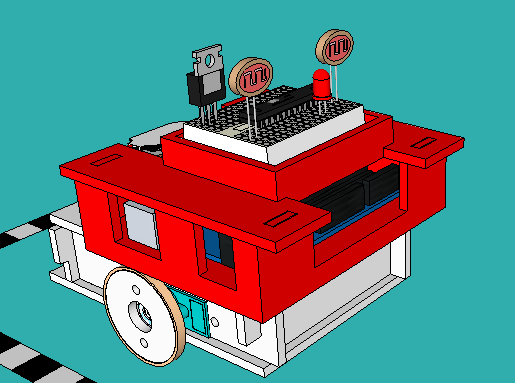

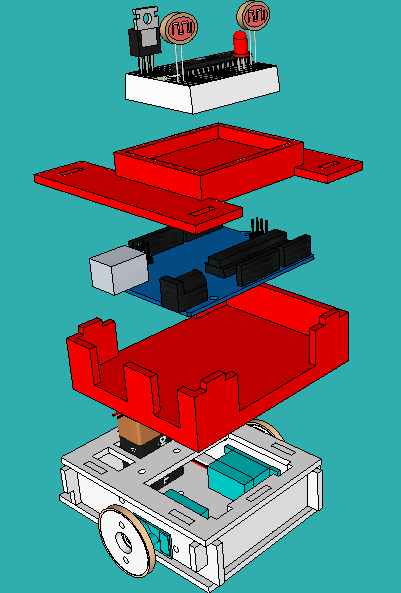

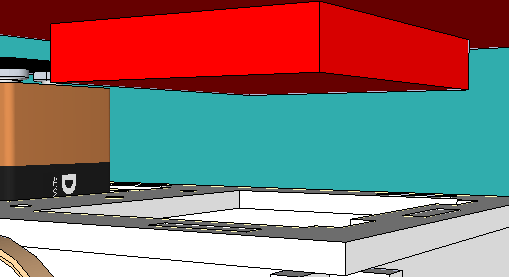

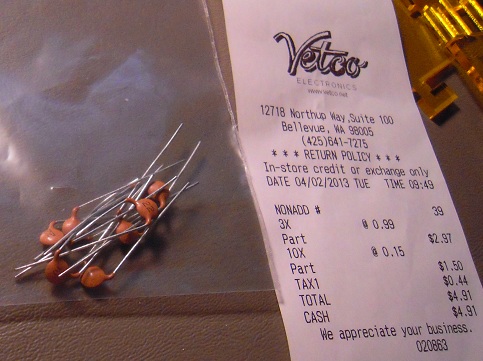

As for the photocell, it does not permit enough current to run the motor, even in the brightest light. So I made a design to include a transistor as amplifier:

And how well does it work now? Too well. Even in the dimmest light, the motor runs at full speed.

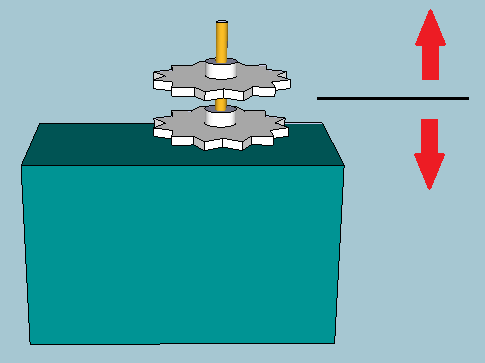

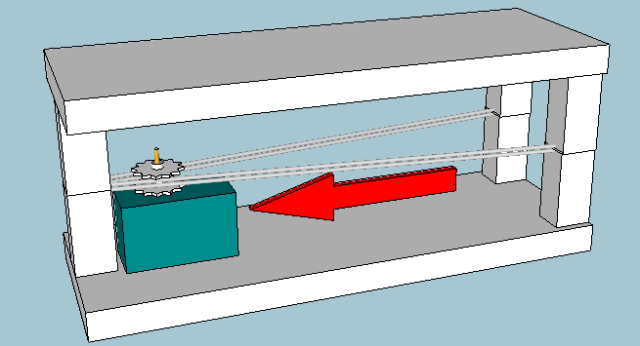

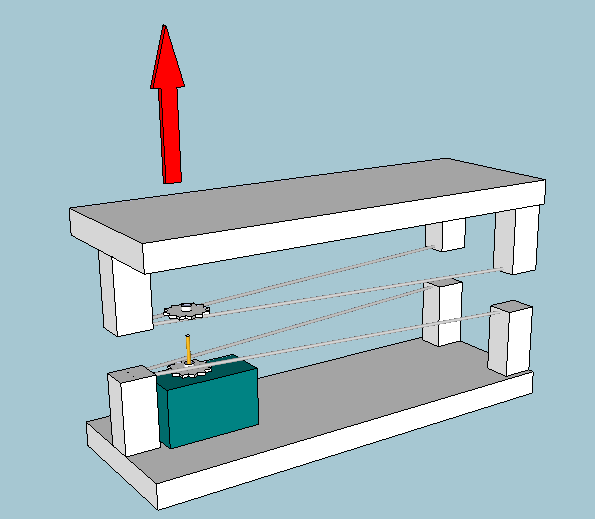

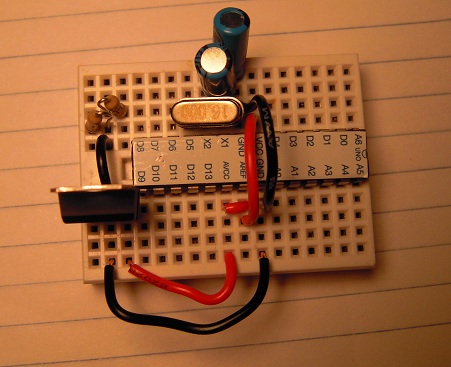

I have ordered some ATTiny45s which will be here by Friday. With a microcontroller, it should be possible to read the photocell and adjust the motor accordingly. Also, I might be able program some interesting behaviors into the brushbot, maybe even steering (I understand it’s all a matter of shifting weight).

Imagine being able to program ‘dances’ and ‘tunes’ into the brushbot via PC, tablet, or smartphone app.