For some time now, the biggest roadblock to implementing my robot has been with screen communications. Now and then the path data transfer procedure works perfectly, other times it doesn’t work at all. I suspect it has something to do with screen illumination intensity and ambient lighting.

Hence, I wanted to make a light calibration procedure. I thought long and hard about this, and visualized creating a special control code for light calibration, and having a sequence of alternating light and dark flashes with the robot then figuring out the average and using that as the break between light and dark flashes signifying 1s and 0s.

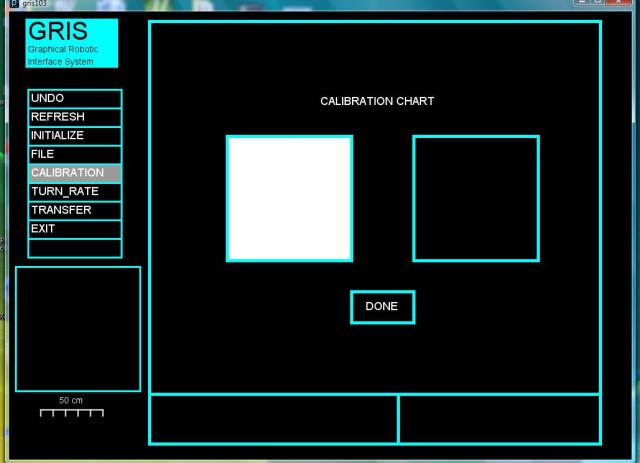

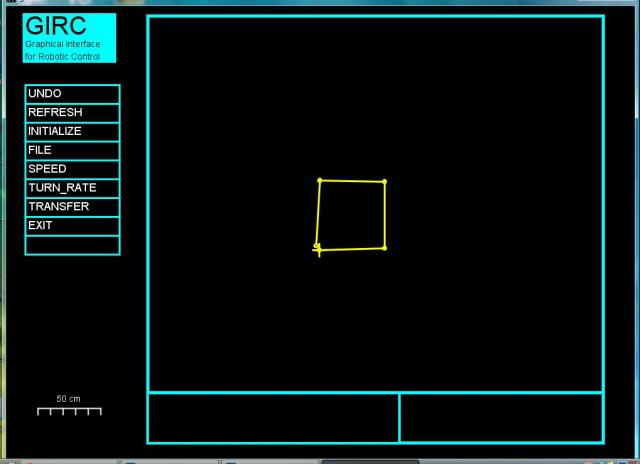

Then this simple chart occured to me:

The only required change to the GRIS laptop program was to create a chart procedure. Not very hard: you click on the CALIBRATION menu button to call it up, then click on DONE when you’re finished. Oh yeah, you have to blank and refresh the work space too. But not that big a deal.

The finesse, as we say in robotics, is on the receiving side. I must program the robot to enter calibration mode and read the light intensities of the two squares (the user will be prompted to move the robot from one square to the other). The robot will then take the average. This will be a lot simpler than what I was planning at first.