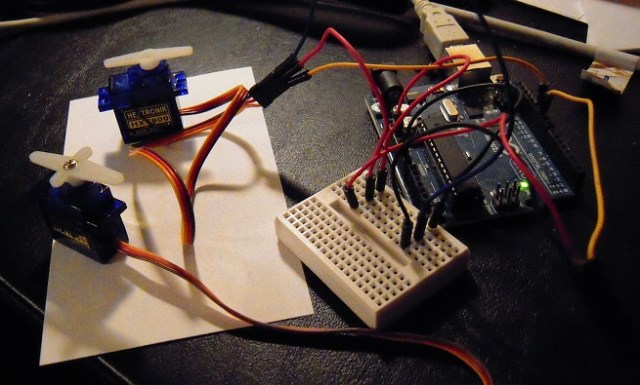

Due to popular demand, here is the source code for my blog entry, “PC to Arduino to LED Control.”

First the Processing Source code:

// ButtonProc // Make a button on the screen that can be clicked // and cause an LED to turn on and off in synch on // the Arduino. Used in conjunction with ButtonArd. // import processing.serial.*; Serial myPort; // Create object from Serial class int val; // Data sent to the serial port // set ButtonValueY = 0 int ButtonValueY = 0; int ButtonValueR = 0; int ButtonValueG = 0; int ButtonValueB = 0; // set clickflag = 0 int clickflag = 0; void setup() { size(480, 500); smooth(); String portName = Serial.list()[0]; myPort = new Serial(this, portName, 9600); fill(150,150,0); rect(100, 100, 50, 50); fill(150,0,0); rect(100,200, 50,50); fill(0,150,0); rect(100,300,50,50); fill(0,0,150); rect(100,400,50,50); } void draw() { // IF the mouse not pressed // THEN clickflag = 0 and return if (mousePressed) { clickflag = 0; return; } //for when the mouse is pressed: // IF clickflag = 1 // THEN return if (clickflag == 1) { return; } // for the first time that we read the button is pressed: // clickflag = 1 clickflag = 1; // Yellow LED: Is MouseX and MouseY within boundaries? if ((mouseX > 100) && (mouseX < 150) && (mouseY > 100) && (mouseY < 150)) { // Is ButtonValueY = 0? if (ButtonValueY == 0) { ButtonValueY = 1; fill(255,255,0); myPort.write('A'); rect(100, 100, 50, 50); } else { fill(150,150,0); ButtonValueY = 0; myPort.write('B'); rect(100, 100, 50, 50); } // end of ButtonValueY check } // Red LED: Is MouseX and MouseY within boundaries? if ((mouseX > 100) && (mouseX < 150) && (mouseY > 200) && (mouseY < 250)) { // Is ButtonValueR = 0? if (ButtonValueR == 0) { ButtonValueR = 1; fill(255,0,0); myPort.write('C'); rect(100, 200, 50, 50); } else { fill(150,0,0); ButtonValueR = 0; myPort.write('D'); rect(100, 200, 50, 50); } // end of ButtonValueR check } // Green LED: Is MouseX and MouseY within boundaries? if ((mouseX > 100) && (mouseX < 150) && (mouseY > 300) && (mouseY < 350)) { // Is ButtonValueG = 0? if (ButtonValueG == 0) { ButtonValueG = 1; fill(0,255,0); myPort.write('E'); rect(100, 300, 50, 50); } else { fill(0,150,0); ButtonValueG = 0; myPort.write('F'); rect(100, 300, 50, 50); } // end of ButtonValueG check } // Blue LED: Is MouseX and MouseY within boundaries? if ((mouseX > 100) && (mouseX < 150) && (mouseY > 400) && (mouseY < 450)) { // Is ButtonValueB = 0? if (ButtonValueB == 0) { ButtonValueB = 1; fill(0,0,255); myPort.write('G'); rect(100, 400, 50, 50); } else { fill(0,0,150); ButtonValueB = 0; myPort.write('H'); rect(100, 400, 50, 50); } // end of ButtonValueG check } }

And here is the Arduino source code:

int incomingByte = 0; // for incoming serial data void setup() { Serial.begin(9600); // opens serial port, sets data rate to 9600 bps // initialize the digital pin as an output. pinMode(13, OUTPUT); pinMode(12, OUTPUT); pinMode(11, OUTPUT); pinMode(10,OUTPUT); } void loop() { // act on data only when you receive data: if (Serial.available() < 1) { return; } // read the incoming byte: incomingByte = Serial.read(); //yellow LED if (incomingByte == 65){ digitalWrite(13, HIGH); // set the LED on } if (incomingByte == 66) { digitalWrite(13, LOW); // set the LED off } //red LED if (incomingByte == 67) { digitalWrite(12, HIGH); // set the LED on } if (incomingByte == 68) { digitalWrite(12, LOW); // set the LED off } //green LED if (incomingByte == 69) { digitalWrite(11, HIGH); // set the LED on } if (incomingByte == 70) { digitalWrite(11, LOW); // set the LED off } //blue LED if (incomingByte == 71) { digitalWrite(10, HIGH); // set the LED on } if (incomingByte == 72) { digitalWrite(10, LOW); // set the LED off } }

You should be able to copy and paste this into the Processing and Arduino IDEs without any trouble. I’ll try to provide support, but I apologize in advance for being distracted with other stuff at the moment.