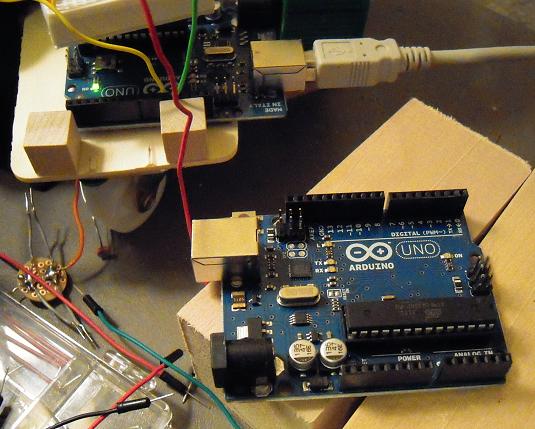

Ever since I was informed that Radio Shack was going to sell Arduinos, I’ve been swinging by the local store to check what they have in stock. Well, last night there was a Mega and a motor controller shield on display, which are relatively specialized applications for new users and I won’t be surprised if the store has trouble moving the merchandise. The basic Uno, which would obviously have the widest appeal to the masses of Arduino-neophytes walking in off the street, was nowhere to be found on display.

I asked the associate if there were any Unos around, and it turns out there was one under the counter that had been opened and returned. So I bought that. It cost $34, compared to mid-twenties for Amazon, but okay, I expect the convenience of retail to cost more.

“What does it do?” the clerk asked.

“It’s a microcontroller,” I said.

“Oh,” he said.

Well, maybe I should have elaborated. These days Radio Shack clerks are knowledgeable about cell phone contracts, not so much electronic components, though maybe that will change.

(And yes, the Arduino technically isn’t a microcontroller, it’s a prototyping platform, but I don’t think he would care enough for me to go back and apologize for my misstatement and explain the difference.)

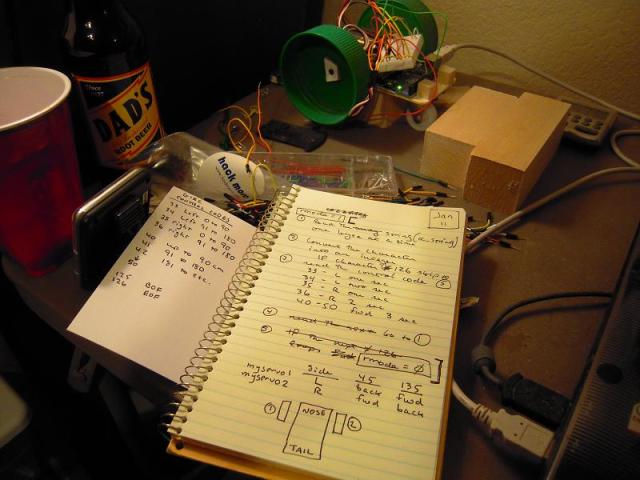

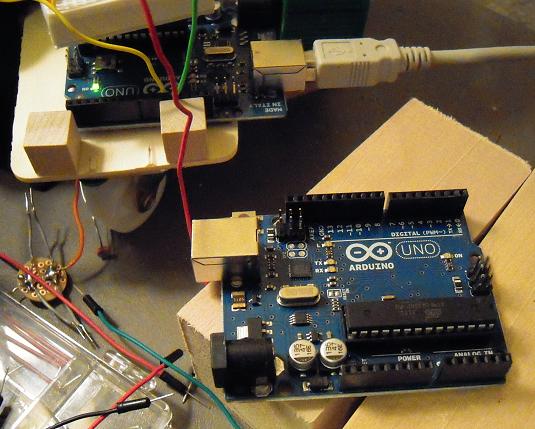

As soon as I got home, I connected it to the USB cable — and got an error message on my computer saying it could not find the driver. More error messages followed when I tried to load the pin 13 LED blink sketch. I began to suspect why the unit might have been returned. It’s not defective, it’s just that there is a learning curve with respect to drivers and comm port assignments and all that (even the zip file format presented problems).

Anyway, after an hour of my bumbling around, it appears to work okay now.

Now as for the following comments, I admit that I’m only a customer, but then again, I am a customer and most businesses do care what customers think and I assume Radio Shack is the same way. So based on that qualification, here are some additional comments about the retail presentation:

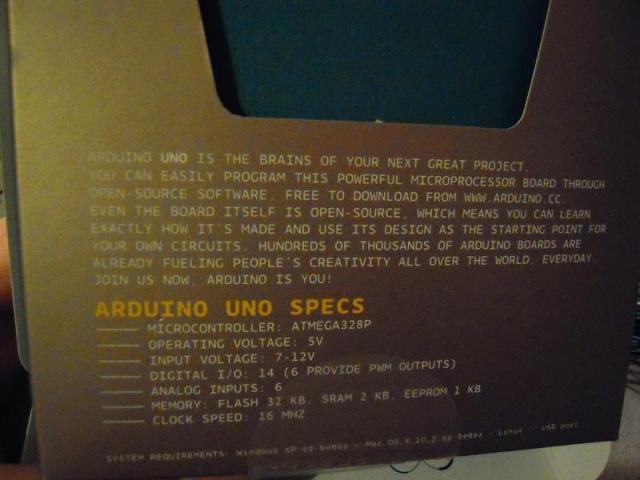

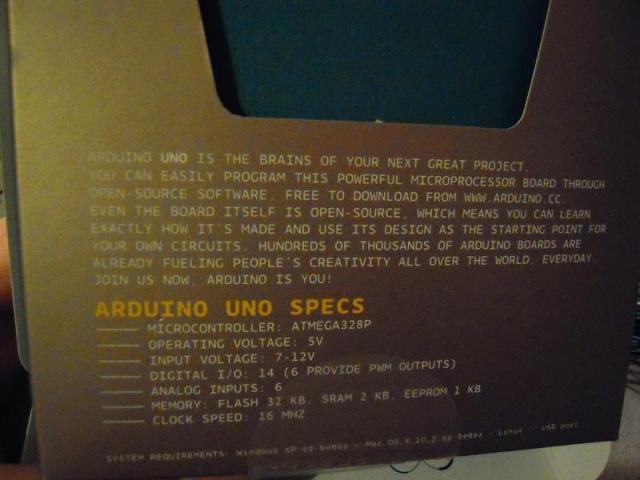

The display box is very attractive, like a work of art, but (assuming the original purchaser didn’t fail to repack it for store return) there is very little documentation inside. I would recommend that the back of the box should specifically mention that getting-started documentation (and not just free software) is available at arduino.cc and that a USB A-to-B cable is required for connection to a PC.

Keep the front and side box graphics by all means, but to enhance readability for those of us with weaker eyesight the printing on the back should be darker letters against a brighter background (or vice versa) — and please, not all capitals!

Well, decide for yourself:

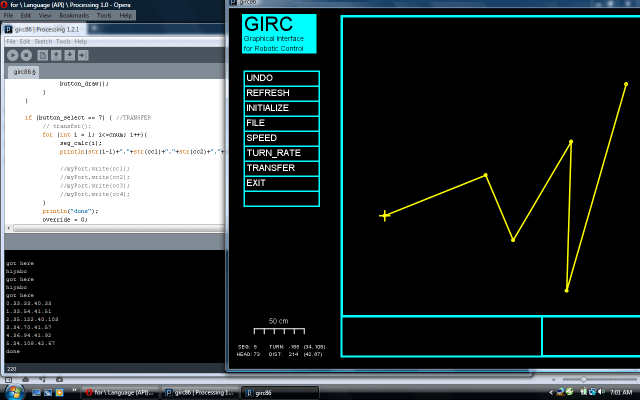

As for shelf presentation, I would recommend that for now Radio Shack limit its Arduino display to:

1. The Uno.

2. The book Getting Started with Arduino.

3. A ‘starter kit’ containing a USB a-to-b cable, a mini breadboard, and a package of LEDs and resistors and flexi-jumpers to perform the examples in the book.

If sales volume builds, then expand the product line’s shelf presence of course.

Retail sales associates obviously don’t have the time to be trained in everything that a microcontroller/prototyping-platform can do, but they should at least be able to tell customers, “Oh, you can connect it to your computer and program it to turn on lights and run motors and read temperature sensors and things like that.”

Please note, these comments are offered in the spirit that having the Arduino at retail level is cool for hardware hackerdom. I’m happy that Radio Shack is selling the Arduino, and I hope that the endeavor is a success for everyone concerned. (And if someday my robot kits can get in on that success, that would be great too!)