“Robots to the Rescue,” Technology Review (29 March 2011):

. . . . constructing robots designed to withstand high levels of radiation would be difficult. “For radiated environments, one needs robots that are particularly rugged,” he says. “Such robots typically are rather large, slow, have only a few CPUs and sensors.”

Surely the slowness issue doesn’t apply to teleoperated robots. Commands sent through a fiber optics cable travel at the speed of light, no matter what the exterior radiation level is. And so what if the CPU manipulates the claw in milliseconds rather than microseconds? That’s still too fast for a human operator to notice.

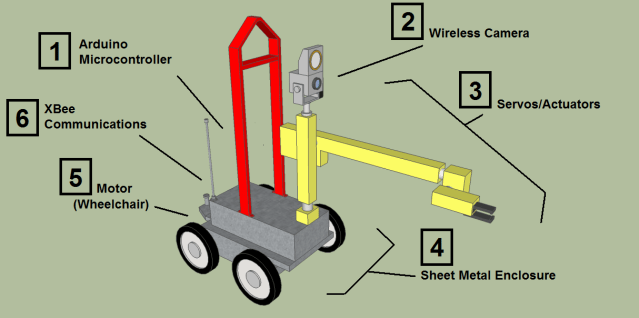

Radiation also has relatively little effect on bulk electronics like batteries, power supplies, servo motors, etc. A radiation environment high enough to affect a 24 DC motor is barely this side of a nuclear bomb detonation.

We don’t have to shield an entire robot. Just the vulnerable microelectronic circuitry that forms the “brains” and sensors.

I find it hard to believe that even the microelectronics would be more vulnerable to radiation than humans are. After all, the debate about whether cell phone radiation affects human brain tissue is in the news all the time, but we seldom if ever hear any concern over whether the same radiation affects the cell phone itself.

Even if the radiation in a damaged nuclear plant is sufficient to damage electronics, wouldn’t it be better to simply replace a burn-out module in a robot, on-site, rather than having to hospitalize a human worker due to overexposure?

As I recall from my brief, unhappy days in nuclear power, radiation is attenuated by a factor of ten by a two-inch thickness of lead. It’s got to be a lot easier to encase electronic components in a lead box than to shield an entire human body.

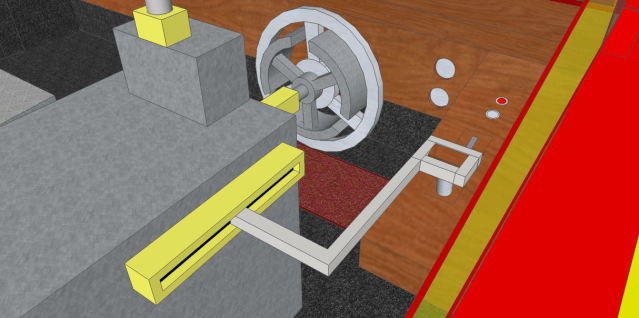

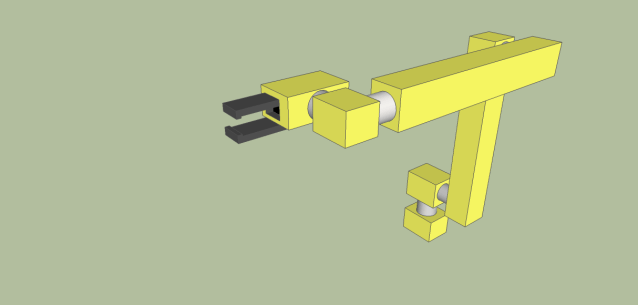

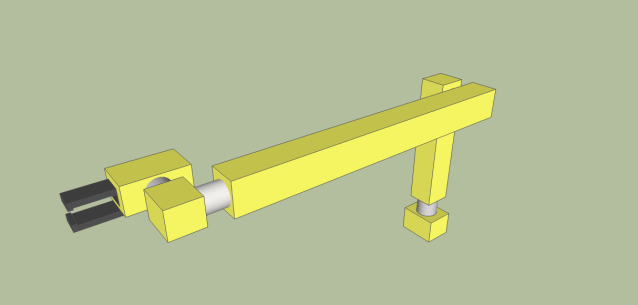

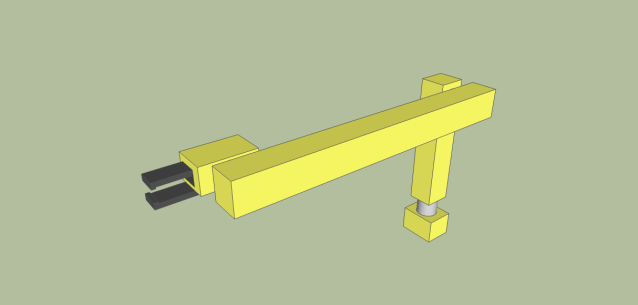

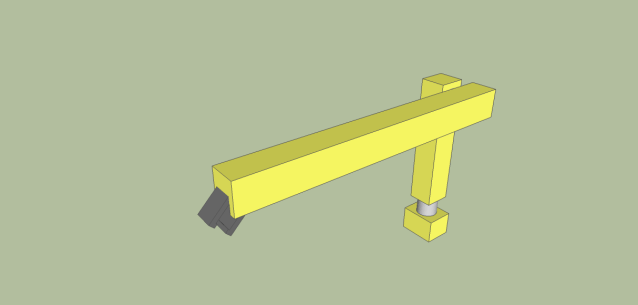

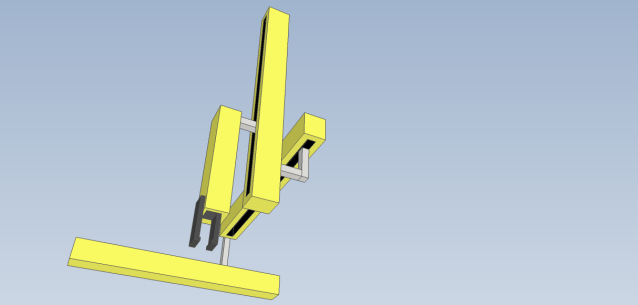

Even cameras could be protected, by using periscope configurations. The camera would be placed in a thick, shielded box with mirrors:

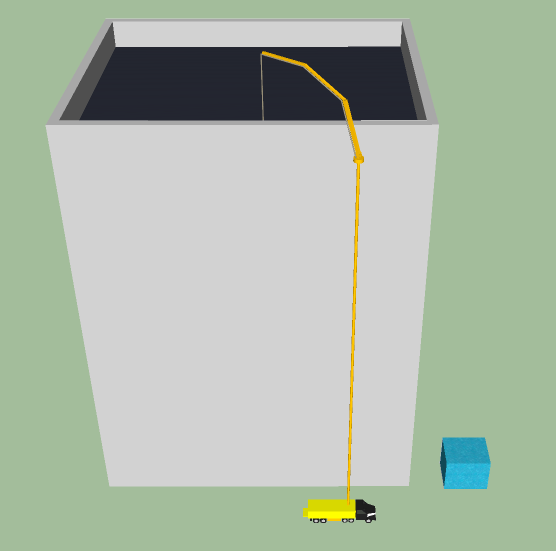

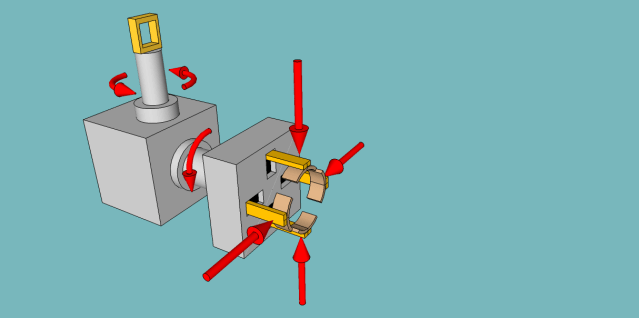

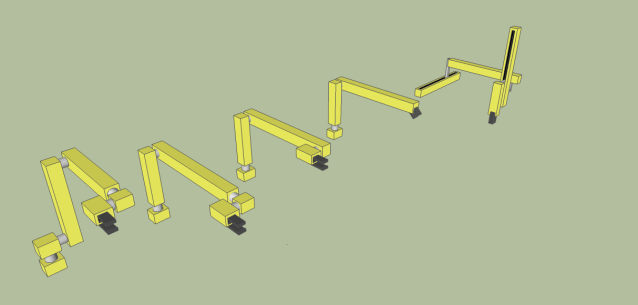

Then a tube is mounted atop the box with mechanisms to tilt and turn the upper mirror:

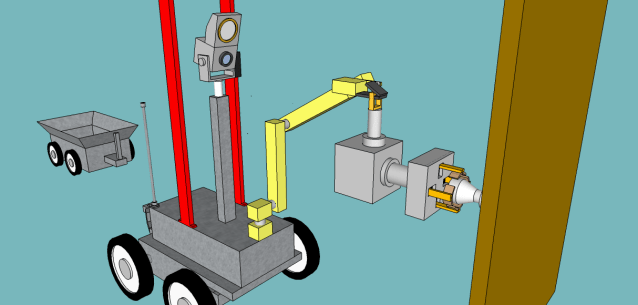

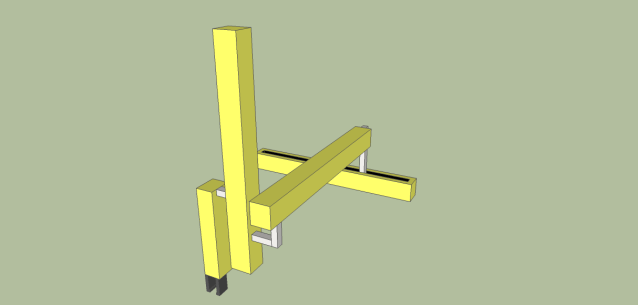

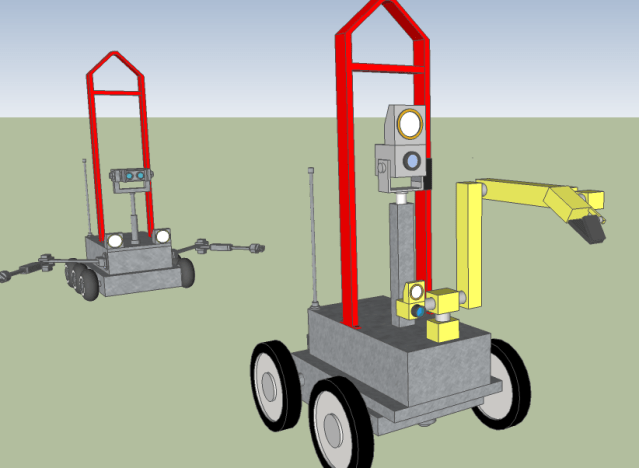

And in turn the periscope assembly is mounted on the robot:

Now, judging from this illustration, I can see that I need to rescale my robot, because video cameras are much smaller than I’ve been showing. That in turn would minimize the size of the protective lead box.

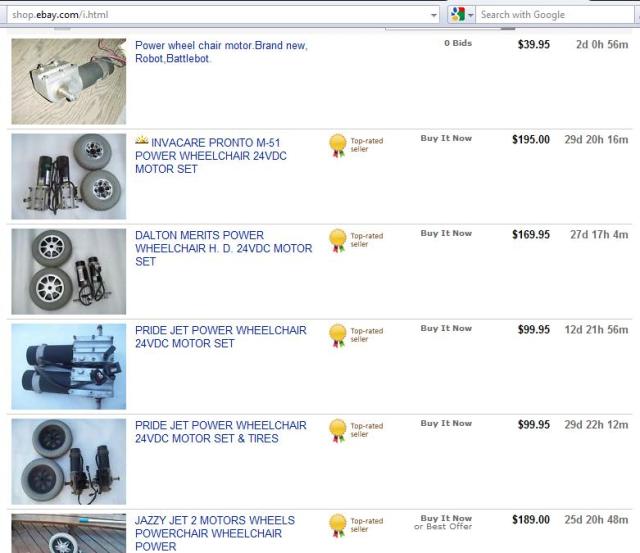

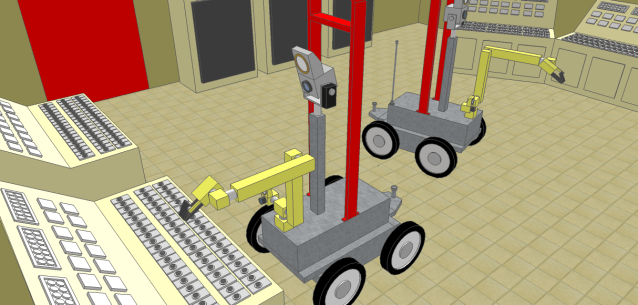

But would the lead box still have to be so heavy that the robot couldn’t move? Many hobbyist robots these days are powered by wheelchair motors, which can carry a hundred kilograms or more. A small lead lined box two inches thick would weigh less than this. Even four inches is possible, and that would attenuate radiation by a factor of a hundred.

Anyhow, how much radiation are we talking about before conventional electronics breaks down? I came across this statement at eHow.com: “Ionization on electronics from nuclear radiation can damage semiconductors within devices for long periods of time after only 5,000 rads of radiation.” ‘Only?’ That dose is five times more than is needed to kill a human worker in a day.

I hope someone reading this will send me a link to numerically-specific (as opposed to general-concept) information on how much radiation it takes to kill electronics.

But until then, I remain convinced that conventional electronics can fare better against radiation than can human beings. Therefore, as much as possible, teleoperated robots should replace human presence in high radiation environments.