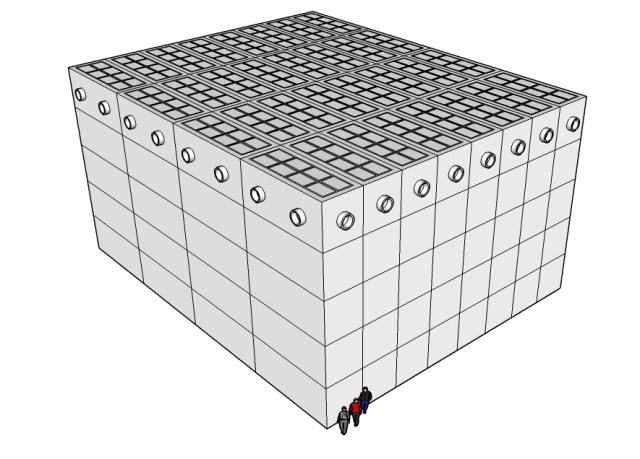

The basic idea is to put a containment box over the oil well. The box is constructed from intermodal shipping containers (aka TEUs — twenty foot equivalent units). It can be assembled on the ocean floor. The TEUs can be welded into modules of two or more on the surface to save time.

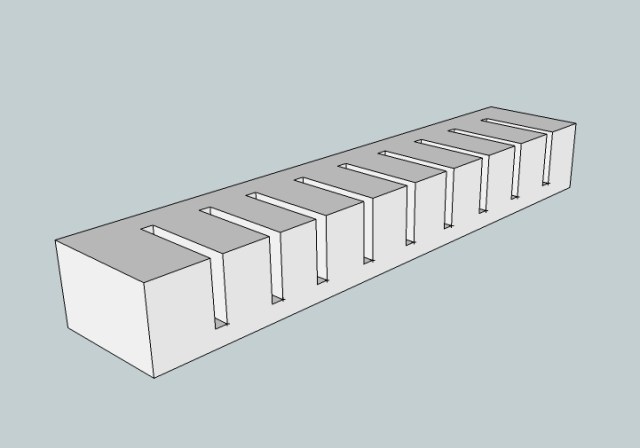

The illustration is somewhat misleading, because it gives the impression that the TEUs are intact inside. In fact, most of the TEU interior walls will be cut away to allow liquid (water or oil) to freely circulate within the interior. TEUs can be cut with conventional handheld power saws. This of course will be done above water by humans because that will be much faster and cheaper than doing it underwater by ROV.

The roof is covered with relief hatches. The design is very simple. If the pressure is great, it pushes the hatches up and the pressure is relieved. Approximately 4000-5000 square feet of hatch area is available. Assuming that the well head is approximately 8 square feet, this would be a reduction in pressure by a factor of 500 or more. Thus, if the wellhead is at 5000 psi, the relief hatches would have a pressure of only 10 psi. The pressure will go up if you close the hatches without venting through the valves.

There are 32 riser hook-up valves along the walls. At a gusher rate of 4,800,000 gallons per day, this would be 150,000 gallons per day per valve, and a flow rate of only 1.8 gallons per second per valve. Each valve is one foot wide, which would indicate a linear flow rate of about four inches per second.

The market rate for TEUs is $1300, so that the 160 TEUs used in the device would cost $210,000. Assuming that one TEU is welded per hour per ROV, and that two ROVs are involved in welding, the entire structure can be assembled within 80 hours, or just over three days.

A great advantage of the cap housing is that it exerts no back pressure on the well. Thus it will not cause greater leakage in seabed fissures.

The housing will leak, but this can be resolved over time (ie, days) by caulking the joints. Piling can be driven against the base of the structure to prevent oil leakage from underneath, but as oil floats to the top and only water would be present at the bottom, this should not be a problem.

The housing is not meant to be a pressure containment. Rather, it is meant as a transition from the current gusher situation to a controlled situation where all oil from the well is utilized at the current flow rate. At the beginning of the transition, all the relief hatches on the roof are open and the internal pressure within the housing is equalized with the outside environment. As hookups begin pumping water and then oil from the interior, however, pressure within the housing will decline until the relief hatches close. The relief hatches are simple gravity devices with no moving parts.

Shipping containers are available universally in quantities of thousands.

If at a later date it is desired to seal off the well, the housing can be readily removed by attaching floatation devices, as its total mass is only 400 tons (5000 lbs per container). An air-filled tank of approximately 30 feet diameter would be sufficient to provide neutral buoyancy in the lifting operation.

To summarize: a large oil spill cap/housing constructed from shipping containers.

Advantages: simple, cheap, fast. Safety is maximized because pressure is kept low. Since the initial goal is not to stop up the well but to divert spillage into revenue pumping immediately, it is also the most profitable solution as well.