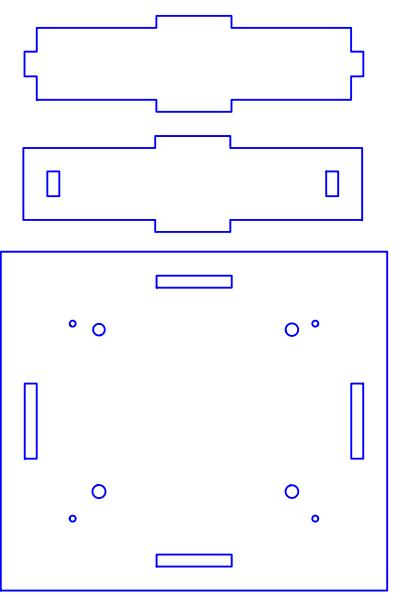

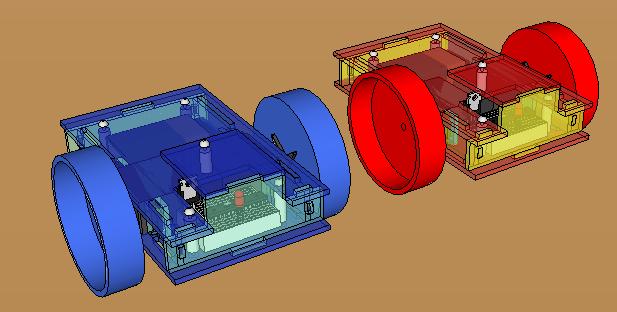

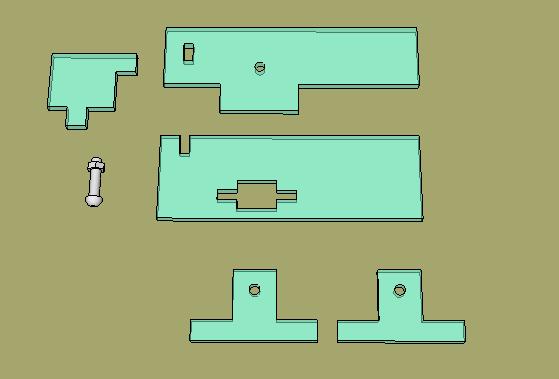

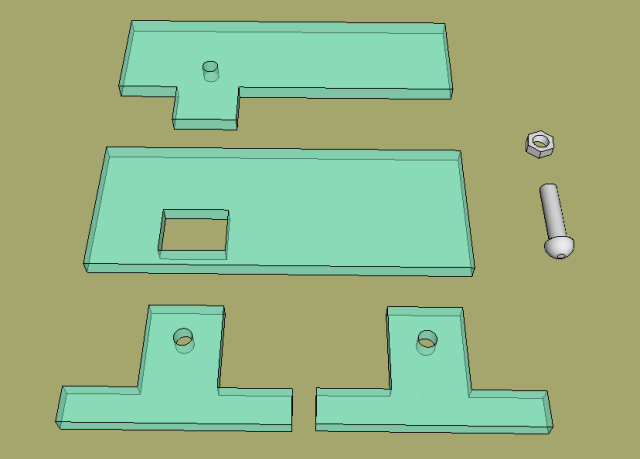

I previously mentioned using the Inkscape trace function to convert a Sketchup exported image file into SVG format. However, it doesn’t seem to be working well enough for laser-cutting. Sure, from a distance it looks okay, like so:

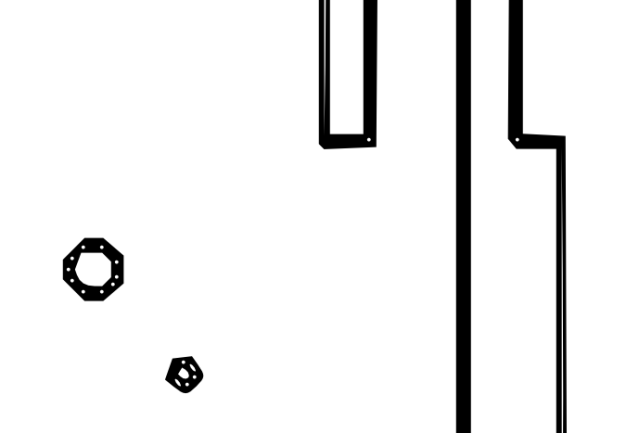

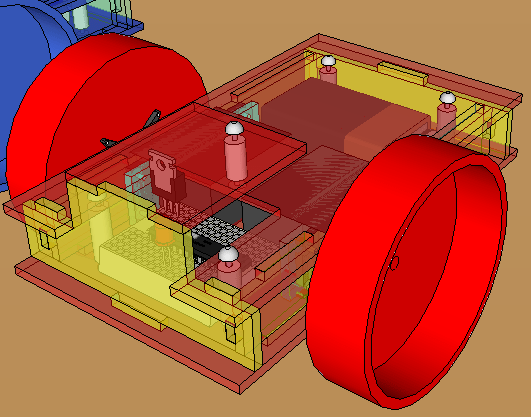

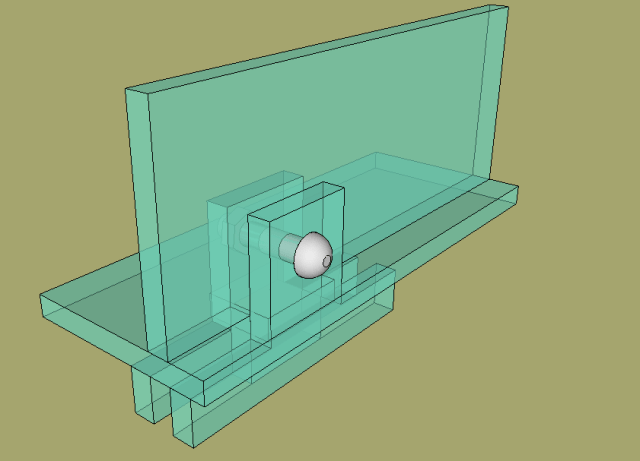

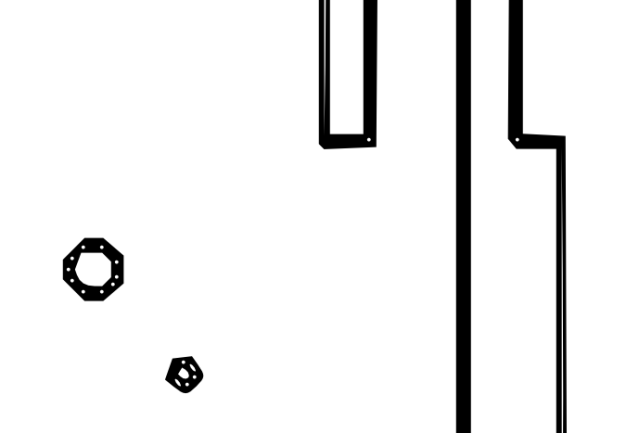

But then zoom in and we see:

I’m not sure what causes these double-bowed lines and bubbles within circles, but I don’t think that a laser cutter will be too happy with this file. Maybe there’s a way to clean up this image inside Inkscape, but I haven’t found it yet.

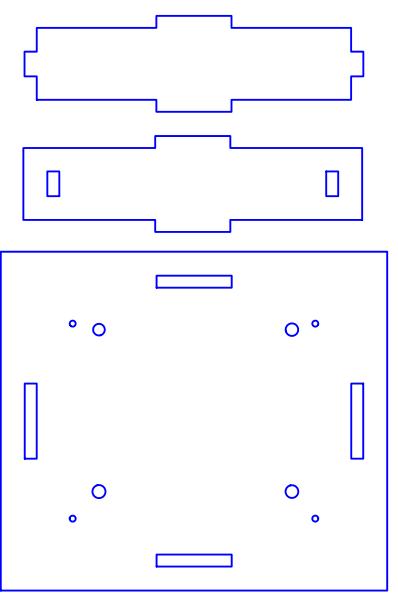

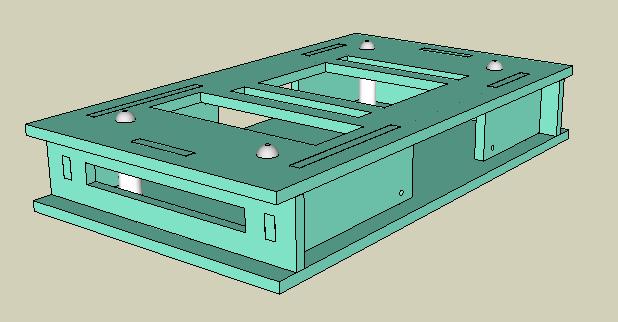

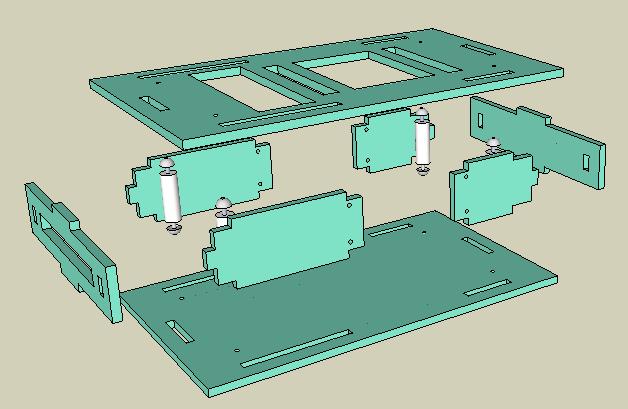

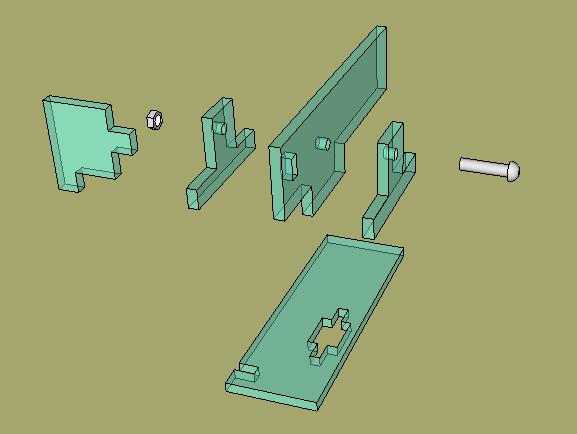

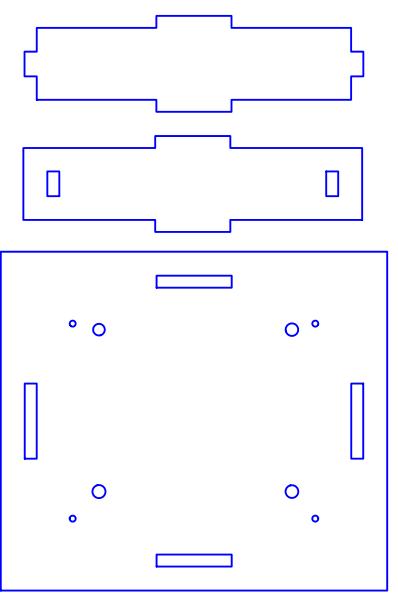

Fortunately, there is an SVG plugin for Sketchup which produces results like this:

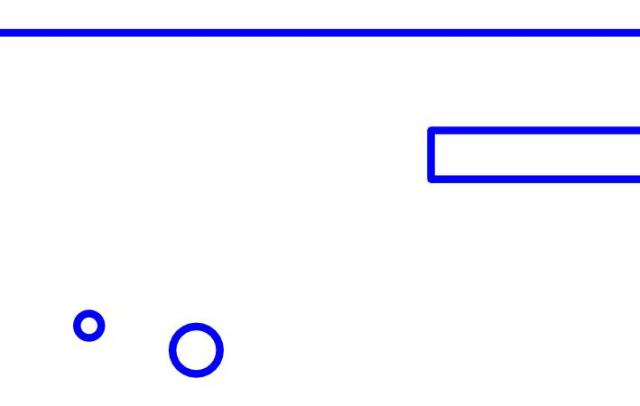

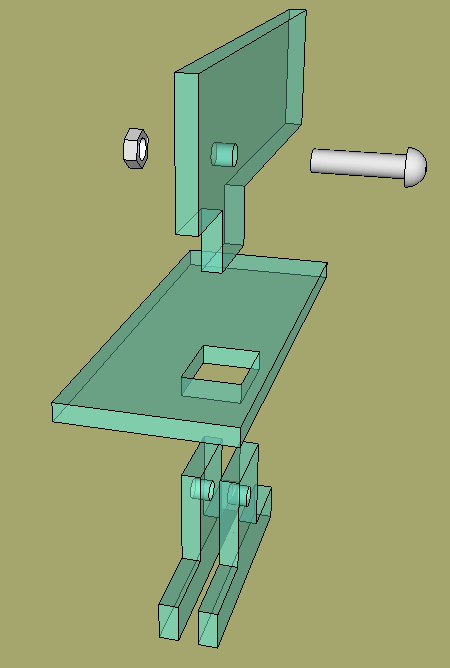

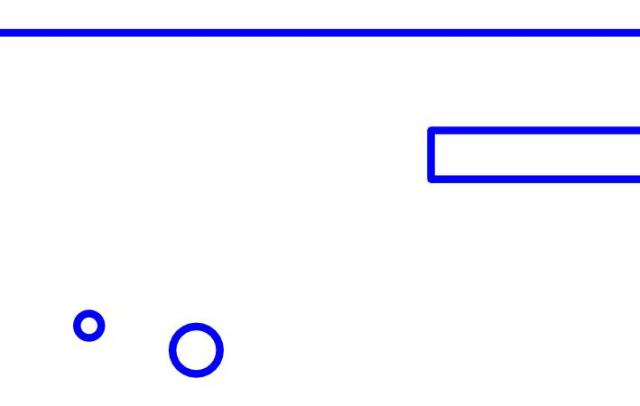

And in close-up:

(Please note, I had to convert the SVG files to other image file formats in order to be viewed in WordPress.)

The SVG plugin wiki is here.

The SVG plugin appears to work great and I recommend it. However, as is often the case, I learned a few things about installation and adaptation on my particular system configuration that aren’t fully covered in the instructions:

1. Vista wouldn’t let me unzip a file directly into the Sketchup plugins folder. However, once I unzipped the files, I could use the conventional method of transferring files into the plugins folder.

2. The flightofideas.rb file has to be placed directly under the Plugins folder at the same level as the FlightofIdeas folder. If you don’t have the .rb file there, Sketchup’s extension list won’t include the folder name.

3. When exporting from Sketchup into SVG format, you’re asked to select a ‘border.’ If you select a border of 10 mm, you’ll end up with the bows and bubbles as before. Selecting 1 mm seems to work okay. With respect to the laser cutting, I’m not sure about the lines or path selection at the time of this writing.

4. For some reason, the pieces within the group got physically rearranged from the layout in Sketchup. I had to load the SVG file into Inkscape to reorient the pieces back into the original acrylic-conservative layout.

I sense that I’m still thrashing through the fog here, but at least now I have my pieces in a nice clean vector format. It is one more step for the Robot Builder on the mystical journey from Sketchup to Acrylic.